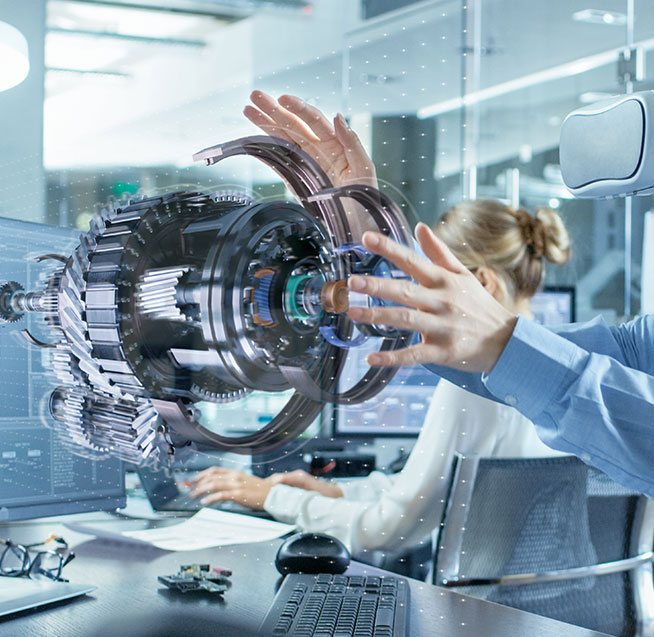

When an organization comes to know about complexity of an existing machine or product they need to contact an expert of reverse engineering like ESC Works Pvt. Ltd. We break down initial parts for analysis in term of design only. Our experienced engineers are there to give you 3D model of any component that an organization need to examined.

Reverse engineering using 3D scan data is the most efficient way to generate a CAD model from a physical object that has any kind of complex or freeform shape. While using traditional measurement techniques such as calipers to reverse engineer these complex surfaces can be difficult or even impossible, 3D laser scanning shines – literally! Although this scan data can easily be turned into a model representing its as-built shape.we specialize in creating models that match original as-designed features – even parametric ones.

ESC Works Pvt Ltd is one of very few design consultant that been approached directly by organizations in need of reverse engineering.

More specifically to examined, rebuild, archive, or alter existing machines, systems and more. We have been always a cost effective and solution oriented service provider.

At ESC Works we have a methodology to bring result oriented services. We are very keen on small things that can give you an impeccable solution.

Based on our feasibility study we measure current products compatibility and performance.

We conduct this analysis that patent of the product has been infringed to different location. (Optional)

We provide information about competitor’s technology to understand things specifically.

We are there to revive your existing product and its life cycle to implement new world design modifications. Based on our understanding and your repurposing we replace your old technology to New one.

We are also providing service that include documentations about new technology which can be useful in future. (Optional)

We are having practice of multiple applications system pertaining to different scenarios checked for inter-operability or establishing an arrangement between such applications.

We design bug-free measures to overwhelmed initial design discrepancies after the initial testing. We’ll take broken or obsolete software, catch the bugs and fix it.

Our cost-effectiveness and budget oriented pricing is organised to provide greater value compared to Clients.