Material handling equipment’s incorporates a wide range of tools, vehicles, storage devices, tools for transportation, storage, monitoring, repairs and protection of products at all stages of production, distribution or transformation.

There are 4 main categories of material handling equipment

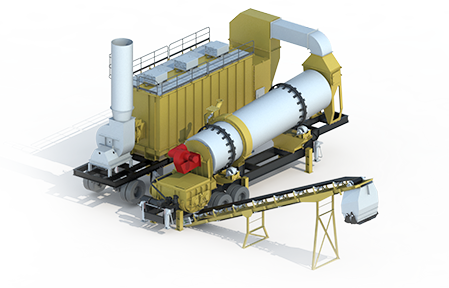

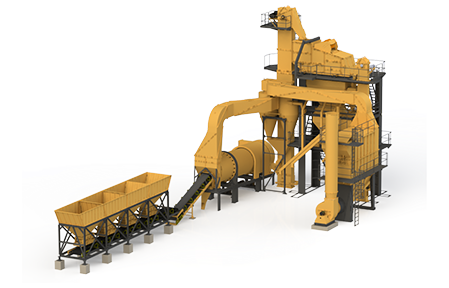

ESC works assist material handling equipment manufacturer to ensure productivity and profitability by speeding up design cycle and reducing design iterations. Our capabilities lie in delivering design support for material handling machinery and equipment.

The handling of bulk materials refers to the storage, transport and control of loose materials in loose form. These materials may include food, liquids or minerals etc.. Generally, these pieces of equipment deal with the items in loose form, such as conveyor belts or elevators designed to move large quantities of material, or in packaged form.

Storage equipment is generally limited to non-automated examples, which are grouped with technical systems. Storage equipment is used to hold or store materials during “downtime” or when they are not being transported.

Industrial vehicle refer to the different types of transport vehicles used to move materials and products in the handling of materials. These trucks have a variety of features to make them suitable for different operations. Some trucks have forks, such as in a forklift, or a flat surface with which to lift objects, while other trucks require a piece of separate equipment to load.

Industrial Vehicle can also be manual or motorized elevators and the operation can be or ride, which requires a user to push them manually or to move on the truck. A stacked truck can be used to stack items, while an unstacked truck is normally used for transportation and not for loading.